An Overview of Saxophone Pivot Screws

By: Curt Altarac

Spring 2022

The type of pivot screws used on a saxophone will impact how the keys are fit and may ultimately affect how the instrument stays in regulation. In this article, we’ll discuss the different types of screws and methods for best fitting each type.

Keys are affixed to saxophones either with rods that pass through the entire length of the key and thread into a post or with pivot screws that secure just the ends of the key. Read this short article for a diagram of each system. There are situations where rods are necessary, such as when multiple keys are functioning on the same axis, as with the top and bottom stacks.

When keys aren’t on the same axis, however, it’s preferable that they be mounted via pivot screws instead of rods. Pivot screw mounted keys tend to be more forgiving if the keywork gets slightly bent or banged around from general or rough use/accidents than rod mounted keys, which can bind or be impeded by friction from misalignment.

Pivot screws thread through the post heads and the tips of the pivot screws secure the key in place, providing a mounting surface on which to rotate. An ideal situation is one where the tips of the screws fit perfectly into the key ends and they are held in place inside the posts so that there is maximum contact between the key end, post face, and pivot screw while also avoiding binding and excess friction.

Manufacturers have long sought to create a method of mounting the keys to the saxophone in such a way that the keys function well without play. The keywork needs to maintain longevity even through use and misuse, the vibrations of the instrument while being played, and the force of the spring tension acting on the key and pivot screws. Balancing these goals with the obvious constraint of ease of assembly and value to the customer is no easy task where pivot screws are concerned. We’ll take a look at different manufacturers' attempts at this and discuss what works well and what challenges the technician faces in order to make the instrument function well.

CRUCIAL ELEMENTS OF PIVOT SCREWS

Headed or headless

The first consideration is whether the pivot screw is headed or headless. Headed pivot screws can only be threaded into the post so far before the head of the screw makes contact with the bottom shoulder of the counterbore in the post. If there is play in the key, you may choose to counterbore the POST. Counterboring is the process of cutting deeper into the post so that the pivot screw can protrude more on the opposite side of the post in order to go further into the key end, as seen in this video.

If the screw causes the key to bind when it is fully tightened and the head is flush with the post, then you countersink the KEY. Countersinking is removing material from the recess of the key end to allow the pivot screw to go deeper into the key, and this is done with a reamer. As of the date of this article, we are working with our Research and Development Team to make new tapered reamers for common brands of pivot screws found in woodwind repair. Expect to see those available later this year.

Headless pivot screws never require counterboring as they can keep being screwed into the post until the key no longer has play. If there is friction or binding in the key, the screw is simply turned back out. These are the simplest type of mechanisms to set up and are undoubtedly the best for longevity. The taper of the pivot screw and the taper of the hole in the key end should match perfectly. Headless pivot screws don’t have the ability to be tightened down, thus keeping it in place. Keeping this type of screw in place is done with a variety of methods, including set screws, locking nuts, thread lock, etc.

TAPER

The next consideration is the taper of the screw, which has 4 main variations.

1. A True Taper is comprised of straight lines that meet at a point, like a cone.

2. A True Taper that is rounded at the tip.

3. A cylindrical end that functions more like a rod.

4. A False Taper which can appear similar to a rounded true taper except that there is a cylindrical section between the tapered tip and the threads.

THREAD PITCH

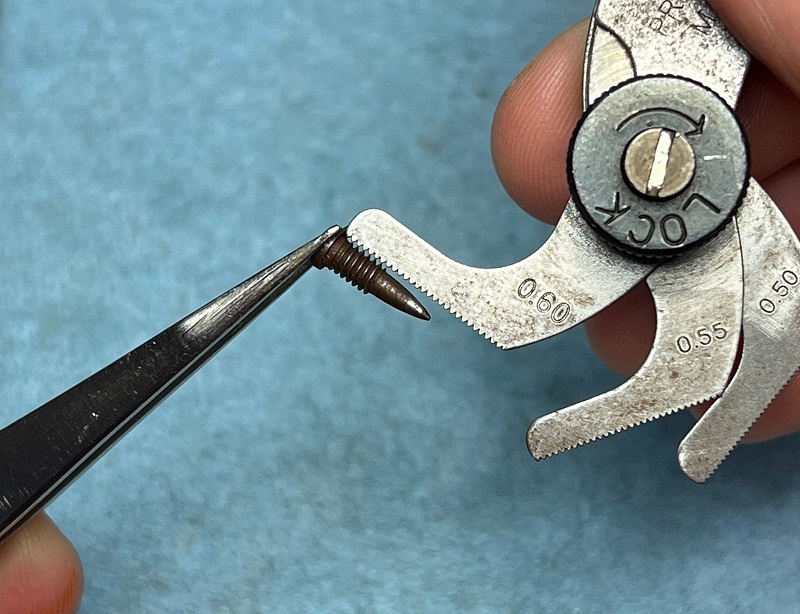

The thread pitch is another consideration. If you’re measuring for a replacement pivot screw on a less common saxophone, you’ll need to know what thread pitch is utilized by the screw. You can figure out this information by measuring the diameter of the threads with digital calipers and finding an exact match with a Thread Pitch Gauge.

KEY END RECESS

The final consideration is the end of the key where the pivot screw meets. This can be a tapered hole, a straight hole, or a tapered hole within a spring loaded bushing. True Tapered pivot screws will have a tapered hole, cylindrical and False Tapered pivot screws will have a straight hole, and modern Selmer series instruments will have the spring loaded bushings.

Assessment and Prep Work

It is important to note that when we are talking about keyfitting and pivot screw fitting techniques, that the body of the saxophone is already straight and dent free, the keys are straight, and the posts are aligned. Keep in mind that the key probably didn’t shrink and that the posts may not have been correctly aligned at the factory. Check for odd key wear and signs of damage or improper assembly by the manufacturer. When fitting pivot screw keys, it’s important to keep the springs disabled in order to check for binding and friction as well as enabling them to check for proper feel under tension.

Pivot Screw Types by Make and Model

Type: Headless Tapered Pivot Screw with Set Screw

Makes and Models: Conn M Series

Conn pivot screws, seen in models spanning from the “Chu Berry” era through the M Series instruments, utilize a variety of headless screws that are locked in place by a set screw that threads into the post perpendicular to the pivot screw and prevents the pivot screw from rotating. This system can work well when the instrument is well maintained, the pivot screws are in good shape, and all of the set screws are present. If there is some play in the key, you simply back the set screw out until the pivot screw can move freely, turn the pivot screw until the key no longer wiggles, and tighten the set screw to secure it in place.

Some challenges that arise are if there is play between the threads of the post and the threads of the pivot screw, the insertion of the set screw can cause the pivot screw to shift and might introduce friction into the keywork. Another consideration is that the set screws are very small and in situations where the instrument isn’t well maintained, they can fall out and get lost. Finding replacement set screws isn’t always an easy task. They can also suffer from rust and get frozen in place. In those situations, oil, heat, and time are the technician’s best friends.

Type: Headed and Headless Tapered Pivot Screw with Thread Lock

Makes and Models: Yamaha

This pivot screw system is self-locking by having a piece of thread-locking material that passes through the threads. This fills the gap between the threads of the screw and the threads of the post and works to hold it in place. It’s much simpler than the methods which utilize set screws or locking nuts. Issues can occur if the thread lock gets damaged or if there is wear in the key mechanism that introduces excessive play. When this happens the thread lock will no longer keep the screw from backing out of the post, and it will need to be replaced.

Type: Headless Tapered Pivot Screw with Locking Nut

Makes and Models: King Zephyr and Super 20

The King locking nut is like the Conn set screw except the nut contacts the post, locking the pivot screw in place. King's version seems to function a bit better than Conn because it's larger, more stable, made of brass, and it pulls the screw by the threads and centers it in the post.

Type: Headed Tapered Pivot Screw with Rounded Point

Makes and Models: Selmer Mark VI, Mark VII, Selmer Super Action 80 Series 1, Keilwerth, Yanagisawa, Yamaha

This type of screw has become ubiquitous in the professional saxophone world. This headed, tapered screw demands an exact mate between the pivot screw taper and the key end taper. While it can take more time during the fitting process due to the inherently small margin for error, the results will yield a stable result without friction or binding. You can expect to be utilizing a pivot screw reamer on the key ends and counterboring the post faces to remove play in the keywork.

Type: Headed Tapered Pivot Screw with Sharp Point

Makes and Models: Martin

The approach to this pivot screw will be identical to that of the headed tapered pivot screw with a rounded point. Precision in your prep work will yield good results.

Makes and Models: Buescher True Tone, early Conn, Bundy

Type: Headed Cylindrical Pivot Screw

It’s best to approach this type of screw as you would a key with a hinge rod. Post alignment is critical with this style of pivot screw system. The cylindrical end of the screw goes into the cylindrical hole in the key end so nothing will stop the key from moving side to side if there is play between the posts.

Type: Headed False Taper Pivot Screw

Makes and Models: Modern economy Asian imports, Cannonball, P. Mauriat

Fitting a false taper pivot screw is one of the biggest challenges for achieving a great and long-lasting setup. This pivot screw may look somewhat similar to the headed True Tapered pivot screw, but it doesn’t function like it and the methods for fitting it are very different. If you look closely you’ll see that the shape is cylindrical until the very end when it is finished with what appears to be a rounded tapered tip. If the posts are too far apart with this system, the keywork is loose and sloppy. If the posts are too close together the key will bind. The key end that mates with the false taper pivot are a straight hole recess that has been filled with finely shredded paper, cork, or leather. When the key is installed the material in the key end compresses around the screw and temporarily achieves a good fit.

This method was created by manufacturers because it is very quick to make an economy line saxophone in this way that feels reasonably good when it leaves the factory. However, it doesn’t take long before the keywork becomes noisy and sloppy, and the technician will have to make some compromises to fit the keys.

The over-the-top fix for this would be to drill out the key ends, replace them with either plugs or Selmer spring-loaded bushings, and replace the pivot screws with headed True Tapered pivot screws. The success of this method will depend heavily on whether the holes in the key ends were centered well at the factory and will also depend on whether the customer wants to make the investment.

A less invasive and time-consuming method for taking play out of the keys is to replace the shredded paper or leather with something more stable as the bearing surface for the pivot screw end. One option is to create a mixture of very fine brass shavings and oil. Another option is to add a bit of soft solder into the key end. Add a drop of oil then apply heat to the key end so that the solder becomes malleable and put the screw in and out of the key to create an appropriately shaped bearing surface that will mate well with the screw. These two methods are fairly permanent solutions and future repairs (of any manner) are still an option.

Makes and Models: Selmer Series II, Selmer Series III

Type: Headed Tapered Pivot Screw with Spring Loaded Bushing

This interesting system utilizes a Headed Tapered Pivot Screw with Rounded Tip. The end of the key is bored out and a spring-loaded bushing is installed. The receiving end of the brass bushing has an exact taper. When the screw is tightened into the bushing, the spring compresses and it has a good and consistent feel. This system reduces the time needed in manufacturing and also saves time in maintenance and setup. The weakness of this system is the difficulty of repairing wear damage where the bushing fits in the key end. Tips on repairing the key ends and fitting bushings can be seen in this video.